Carbon Robotics unveils ‘AutoTractor,’ a self-driving platform to boost productivity on farms

Long gone are the days on the farm where getting up at the crack of dawn to run a tractor through fields might have been just the start of a long day’s work. Now, the tractor could very well have been running all night — by itself. That’s the vision of Seattle agriculture-tech startup Carbon Robotics, whose latest product is called Carbon AutoTractor, an AI-powered, autonomous platform designed to fit on and control existing equipment and serve as an answer to labor shortages and increased productivity in farming. “We learned from farmers that their biggest challenges continue to be around… Read More

Long gone are the days on the farm where getting up at the crack of dawn to run a tractor through fields might have been just the start of a long day’s work. Now, the tractor could very well have been running all night — by itself.

That’s the vision of Seattle agriculture-tech startup Carbon Robotics, whose latest product is called Carbon AutoTractor, an AI-powered, autonomous platform designed to fit on and control existing equipment and serve as an answer to labor shortages and increased productivity in farming.

“We learned from farmers that their biggest challenges continue to be around labor and labor availability,” said Carbon Robotics founder and CEO Paul Mikesell. “If they could, they would run everything 24/7. They would run everything every minute of farming season to get as much done as possible.”

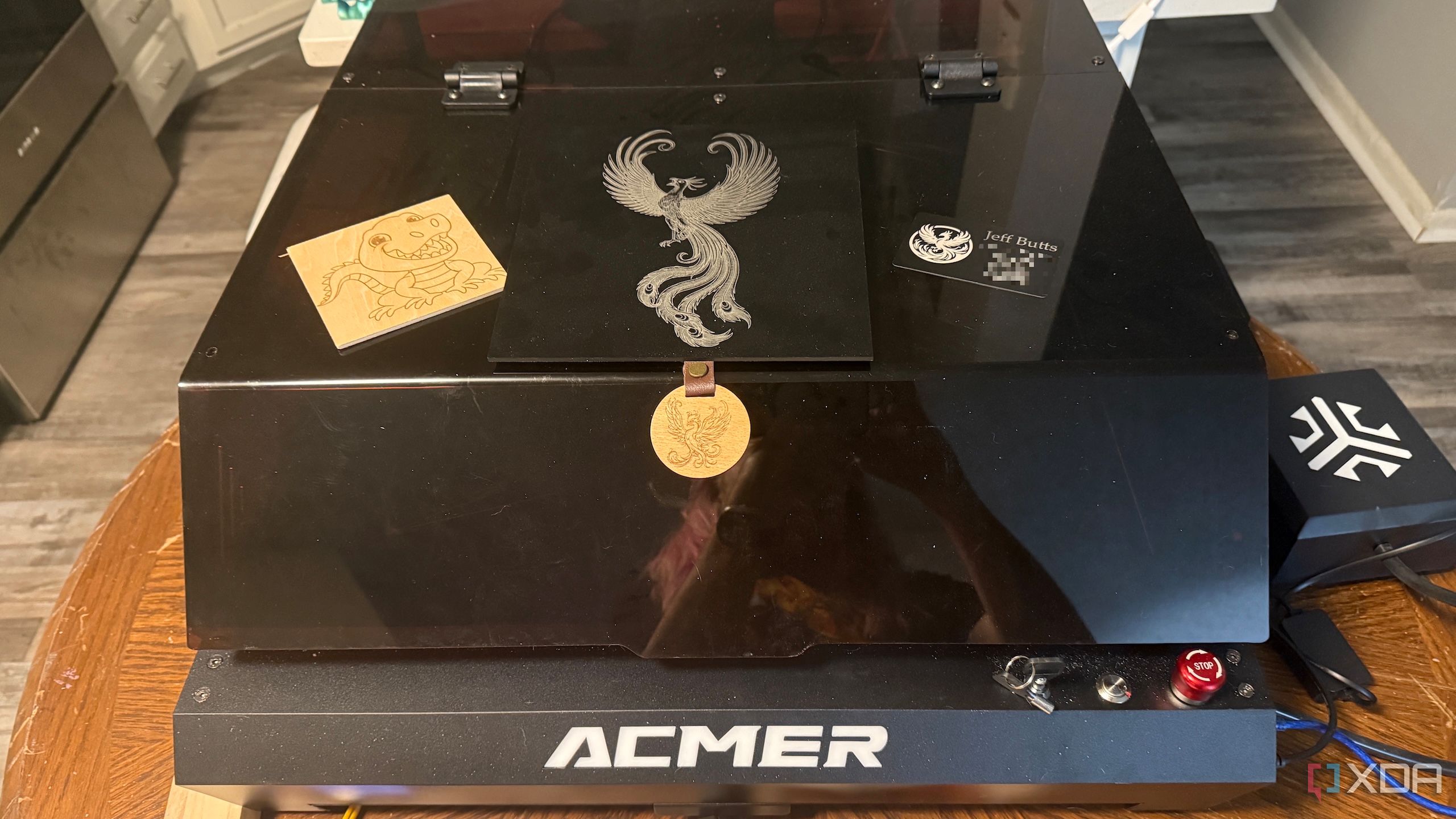

Founded in 2018, Carbon Robotics has been chiefly known for its signature LaserWeeder machinery, which can be pulled behind a tractor and uses an array of AI and computer vision tech to detect plants in fields and then target and eliminate weeds with lasers. The latest version, LaserWeeder G2, was released in February.

Now the automatic weed zapper can be pulled by the AutoTractor.

And Mikesell, the longtime technologist and entrepreneur who previously co-founded data storage company Isilon Systems and led an infrastructure engineering group at Uber for four years, said the AutoTractor eclipses other providers’ attempts at similar autonomy.

The Carbon Autonomy Kit features several components, some of which are mounted on top of the tractor and some inside. It has cameras, a safety radar system, a crash safety bumper, and a box inside the tractor that connects to the electronics and tells the machine how to drive and do its farming activities.

One of the keys to making it all work is a complex supervision and management system, run from Carbon’s Remote Operations Control Center (ROCC) in Richland, Wash. Trained operators can monitor unmanned tractors on farms anywhere in the world and take control in the event that the AutoTractor encounters an unexpected obstacle, such as an irrigation line or wildlife in the field.

“If I have a tractor that I’ve been told is autonomous, and I put it in the field, and I expected it to do eight hours of work, and then I come back after the eight hours and see it stopped 45 minutes into its shift because it got confused by something, well, that’s a real pain,” Mikesell said. “And if it happens time and time again, then it’s just unacceptable.”

The AutoTractor autonomy kit is initially compatible with John Deere 6R and 8R Series tractors, requiring no permanent modifications, according to Carbon. Installation can be completed in less than 24 hours and tractors can toggle between autonomous and manual operation as needed.

Beyond the LaserWeeder, the AutoTractor can pull and adjust to machinery that performs ground preparation tasks such as tilling, plowing, cultivating, ripping, discing, listing, mulching and mowing without an in-cab driver.

Carbon has customers today working acreage with AutoTractor. And Mikesell believes there are more to come, as farmers continue to grapple with the reality of finding enough human workers.

“Labor has been the No. 1 issue since we started this company,” Mikesell said. “The challenge of putting people in tractors for 24/7 farming in the four to six months that any one of these farms is really operating is immense. And it’s limiting their ability to be profitable.”

Carbon Robotics raised $70 million last fall, and has raised $157 million to date. The company employs about 200 people and is ranked No. 13 on the GeekWire 200, our list of top privately held startups based across the Pacific Northwest.

![At a Glance bug causing weather sync issues, forecast delays on Pixel [U]](https://i0.wp.com/9to5google.com/wp-content/uploads/sites/4/2024/03/At-a-Glance-v1.jpg?resize=1200%2C628&quality=82&strip=all&ssl=1)